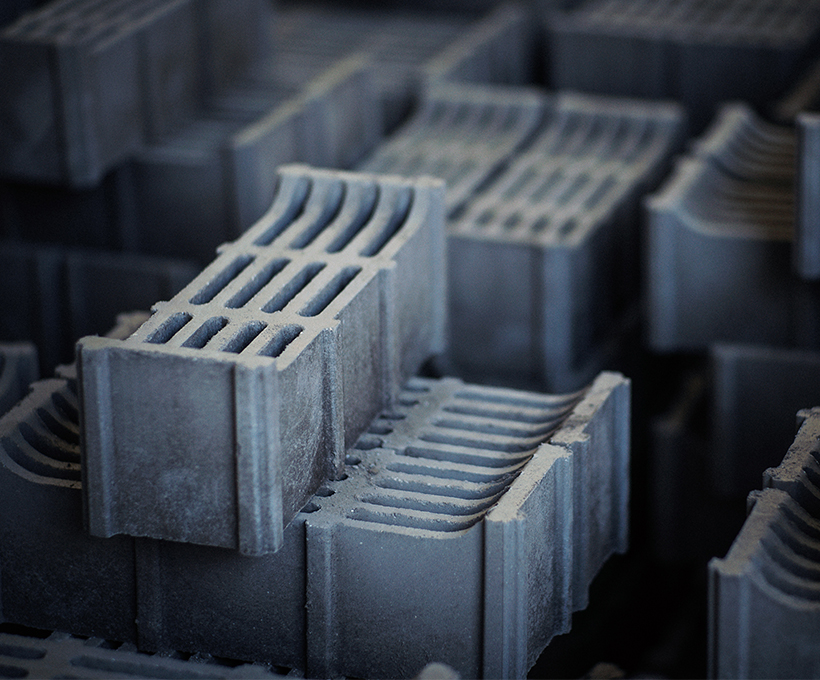

Refractory bricks are essential materials in high-temperature industrial applications. Among the various types, SK32 and SK34 stand out for their unique properties and uses. This article delves into the characteristics, applications, and benefits of SK32 and SK34 refractory bricks.

What Are they?

SK32 and SK34 are types of fireclay refractory bricks. They are made from high-quality fireclay and other raw materials, which undergo high-temperature firing. These bricks are known for their excellent thermal stability and resistance to chemical corrosion.

SK32 Refractory Bricks

It have a lower alumina content compared to SK34. This makes them suitable for applications where moderate thermal resistance is required. They are often used in:

- Blast furnaces

- Hot blast stoves

- Glass melting furnaces

SK34 Refractory Bricks

SK34 bricks contain a higher alumina content, providing superior thermal resistance. They are ideal for more demanding applications, such as:

- Steel ladles

- Cement kilns

- Non-ferrous metal processing furnaces

Key Properties of SK32 and SK34

Both SK32 and SK34 bricks share some common properties, but they also have distinct differences.

Thermal Resistance

They can withstand temperatures up to 1500°C, while SK34 bricks can endure temperatures up to 1650°C. This makes SK34 more suitable for extreme heat environments.

Chemical Stability

Both types offer excellent resistance to chemical corrosion. However, SK34’s higher alumina content provides better protection against acidic slags and alkalis.

Mechanical Strength

SK34 bricks generally have higher mechanical strength compared to SK32. This makes them more durable in high-stress applications.

Applications of SK32 and SK34

Understanding the specific applications of SK32 and SK34 can help in selecting the right material for your needs.

Industrial Furnaces

Industrial furnaces operating at moderate temperatures commonly use SK32. Furnaces requiring extreme heat prefer SK34 for its higher thermal resistance.

Construction Industry

In the construction industry, SK32 is often used for lining chimneys and fireplaces. SK34 is more suitable for high-temperature kilns and reactors.

Metallurgical Industry

The metallurgical industry uses both SK32 and SK34. Blast furnaces typically employ SK32, while steel ladles and non-ferrous metal processing utilize SK34.

Benefits of them

Using SK32 and SK34 refractory bricks offers several advantages.

Cost-Effectiveness

SK32 bricks are more cost-effective for applications that do not require extreme heat resistance. SK34, while more expensive, provides better performance in high-temperature environments.

Longevity

Manufacturers and users recognize both SK32 and SK34 bricks for their long service life. This reduces the need for frequent replacements, saving time and money.

Versatility

The versatility of SK32 and SK34 bricks makes them suitable for a wide range of applications. This flexibility is a significant advantage for industries with varying needs.

Conclusion

SK32 and SK34 refractory bricks are indispensable in high-temperature industrial applications. Understanding their properties and applications can help you make informed decisions. Whether you need moderate thermal resistance or extreme heat durability, SK32 and SK34 offer reliable solutions.

By choosing the right refractory brick, you can enhance the efficiency and longevity of your industrial processes. SK32 and SK34 provide the performance and reliability needed to meet the demands of modern industry.