Address

No.108 Huaguang Road,Zibo City,Shandong Province,China

Work Hours

Monday to Friday: 9AM - 5PM

Address

No.108 Huaguang Road,Zibo City,Shandong Province,China

Work Hours

Monday to Friday: 9AM - 5PM

According to Japanese research on the wear of blast furnace main trough linings, the lining near the taphole suffers severe erosion due to direct molten iron冲刷, with an erosion rate typically ranging from (6.0–8.5) × 10⁻⁶ mm/s. This rate is proportional to the 1.9th power of molten iron flow and the 2nd power of slag volume. In the rear section of the trough, where the iron flow velocity decreases, the wear rate slows down to

In recent years, companies such as Nippon Steel, Krosaki Harima, and Shinagawa Refractories have developed three advanced construction methods—N-Cast (pouring method), VE (vibration molding method), and SVP (dry vibration molding method)—to replace traditional ramming techniques. These methods extend lining service life, improve construction efficiency, and reduce refractory consumption. Their key advantage is that they reuse the remaining lining without removal, minimizing material waste.

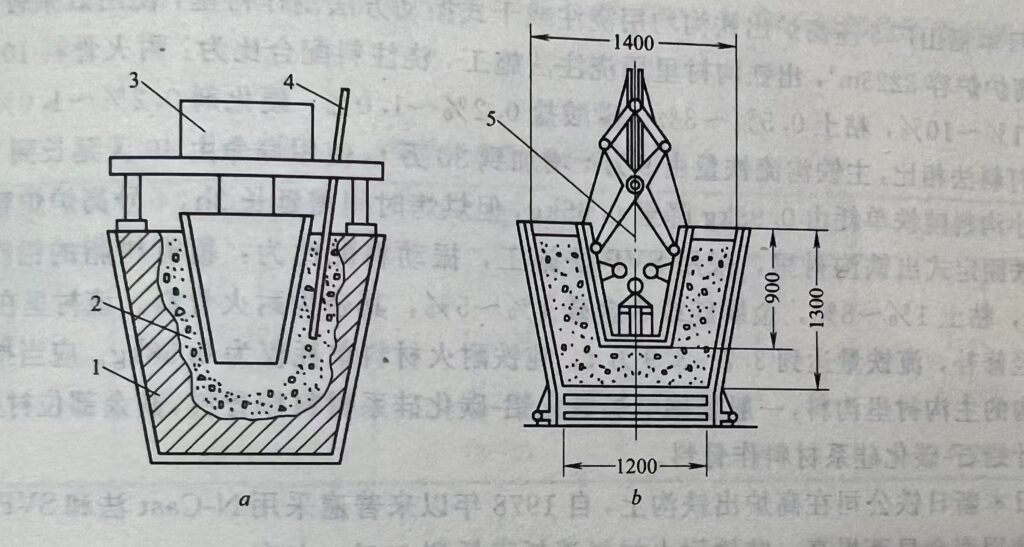

Figure 9-32 illustrates the N-Cast and SVP methods. The construction steps for these techniques are:

Compared to traditional ramming, these methods:

✔ Reduce construction time to 1/10

✔ Cut labor by 80%

✔ Double service life

✔ Lower refractory consumption by 33%