A tunnel kiln consists of four parts: the kiln body, combustion equipment, ventilation equipment, and in-kiln conveying equipment. The kiln body is composed of kiln walls and a kiln roof. The functions and requirements of the kiln walls are as follows:

(1) Together with the kiln roof, the kiln walls separate the kiln tunnel from the outside, allowing heat exchange between combustion products and 坯体 (green bodies) within the tunnel. Therefore, the kiln walls must withstand high temperatures and possess high heat resistance.

(2) The kiln walls support the kiln roof and bear a certain weight, requiring the material to have sufficient strength.

(3) The inner wall temperature of the kiln is approximately equal to the product temperature, while the outer wall is exposed to the atmosphere. Thus, heat from the inner wall dissipates through the kiln walls to the outer wall. To this end, the kiln walls must be thermally insulated to reduce heat loss.

The inner wall materials of the kiln must be heat-resistant, and the types of materials selected are determined by the firing temperature of the products:

(1) Fireclay bricks for use at temperatures below 1300°C;

(2) High-alumina bricks for 1300–1400°C;

(3) Silica bricks for 1400–1500°C;

(4) Magnesium-aluminum bricks for 1500–1600°C;

(5) Corundum bricks for below 1800°C.

To reduce heat dissipation from the kiln walls, lightweight thermal insulation materials such as lightweight fireclay bricks, lightweight silica bricks, and diatomite bricks are laid between the inner and outer walls.

The types and thicknesses of materials for each layer in different sections of the kiln are determined based on the temperature of that section. Once the kiln wall materials and thicknesses are determined, and the kiln structure is decided, a rough estimate of the materials required for the kiln walls can be carried out.

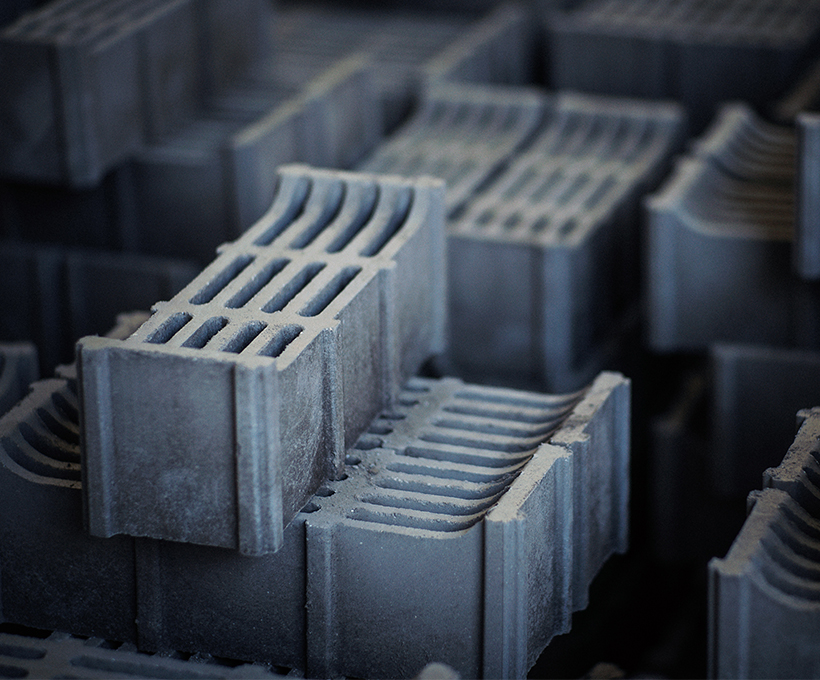

Clay Brick

Hard firebrick is a kind of alumina silicate brick containing 35-45%, and the refractories are SK 32-34. Brick is made of refractory clay, calcined limestone, mullite and other raw materials, with good wear resistance, peeling resistance, corrosion resistance. It has the characteristics of low porosity, high strength, heat peeling, wear resistance, creep resistance, etc., and is widely used in the lining of coke oven, glass kiln, cement rotary kiln, lime kiln, various incinerators and heating furnaces.