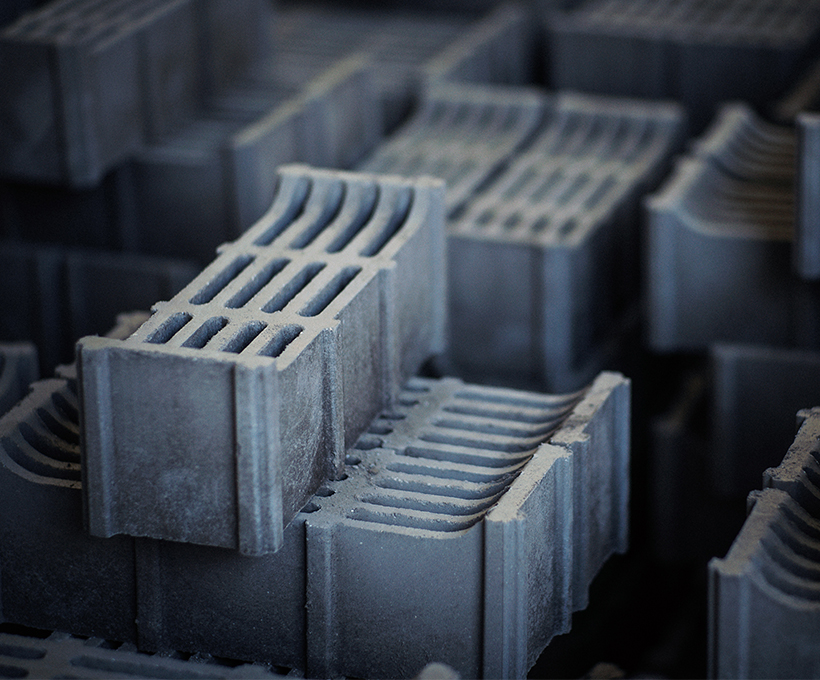

Castables are granular and powdered materials made from refractory substances, combined with a certain amount of binder and water, forming a highly fluid mixture suitable for shaping by casting. To enhance fluidity or reduce water content, plasticizers or water-reducing agents may be added. Additionally, hardening accelerators may be incorporated to promote setting and hardening. Since their basic composition and forming/hardening processes are similar to those of conventional concrete used in civil engineering, such materials are often referred to as refractory concrete mixtures.

I. Characteristics of Castables

Many properties of castables largely depend on the type and quantity of the binder. For instance, in terms of strength (except for those made from lightweight aggregates), since the strength of the aggregate particles is generally higher than that of the hardened binder and the bond strength between the particles and the binder, the strength of the castable is essentially determined by the binding strength of the binder.

Castables typically exhibit higher fluidity than ramming materials. As a result, most castables only require pouring or slight vibration to densely arrange the mixture components and fully fill the mold.

After forming, castables must undergo appropriate measures to promote hardening based on the binder’s characteristics. For example, cement-based castables require curing under suitable humid conditions, while certain metal inorganic salts may need drying and baking.

The high-temperature properties of castables are also closely related to the type and amount of binder. If the selected granular and powdered materials possess excellent refractoriness, and the binder has a high melting point without reacting with the refractory materials to form low-melting compounds, the castable will exhibit high refractoriness. If the granular and powdered materials are fixed, the refractoriness of the castable is largely controlled by the binder. Since, in castables prepared with ordinary calcium aluminate cement, most or even all of the fusible components are contained within the cement paste, the amount of cement significantly impacts the high-temperature properties of the castable.

When cement is used as a binder, during high-temperature service, the cement paste undergoes dehydration, decomposition, and other phase changes, as well as sintering. This results in volume changes and structural transformations in the castable. Since the phase changes in the cement paste vary with temperature, the lining made from such castables develops distinct compositions and structures at different distances from the working surface, forming a layered structure. Between these layers, the formation of different phases may generate internal stresses or even cracks due to changes in specific volume.

In the sintered zone, since the aggregate particles are pre-fired and only expand upon heating, while the cement paste undergoes significant shrinkage, the difference in deformation between the two increases. This severely weakens the bond within the cement paste and between the cement paste and the aggregate particles, making it highly prone to cracking. Local cracks may form at the interface, and even vertical cracks penetrating the working surface may occur. Between the sintered zone and the dehydrated but unsintered zones, horizontal delamination cracks may form. During temperature fluctuations, stress caused by differing thermal expansion rates can lead to spalling along these cracks. Such structural loosening due to dehydration and decomposition of the cement paste, combined with the tendency of layered structures to spall, is often one of the primary factors contributing to the failure of cement-based castables.

II. Applications of Castables

Castables are currently the most widely produced and used type of monolithic refractory material. They are primarily employed to construct monolithic linings for various heating furnaces and other thermal equipment. Some high-quality varieties can also be used in smelting furnaces.

For example, calcium aluminate cement castables are widely used in various heating furnaces and other thermal equipment free from slag or acid/alkali erosion. In areas exposed to molten iron, steel, or slag at high temperatures—such as tap holes, ladles, blast furnace stacks, and runners—castables made from high-purity, low-calcium, high-alumina cement combined with high-alumina, well-sintered aggregates and powders are suitable.

Phosphate-bonded castables, for instance, are extensively used in heating furnaces and soaking pits for metal heating, as well as in coke ovens and cement kilns where direct contact with materials occurs. They are also effective for repairing areas in metallurgical furnaces and other vessels exposed to molten slag or metal. In applications requiring high wear resistance at relatively moderate temperatures, phosphate-bonded castables are particularly suitable. Castables made from corundum-based refractory materials generally perform well in reducing atmospheres.

When used as linings or furnace bodies in thermal equipment, castables should generally be pre-fired before their first use to gradually remove physical and chemically bound water, achieving a degree of sintering and stabilizing their volume and properties. The pre-firing schedule significantly impacts service life. The fundamental principle of the pre-firing schedule is to align the heating rate with the expected dehydration, phase changes, and deformation. During temperature ranges where such changes occur rapidly, the heating rate should be slowed or held for an extended period. Improper pre-firing or immediate rapid heating into service may lead to severe cracking, loosening, or even collapse. In extremely large or thick sections, explosions may even occur.

High Strength Lightweight Insulation Refractory Castable

Refractory castable is a granulated and powdery material made by adding a certain amount of binder to refractory aggregate. It has high fluidity and is shaped by casting. The castable binder produced by our company has high moisture content, good fluidity, high strength and corrosion resistance, and can be selected according to the conditions of use. It can be directly poured into the lining body, and can be made into prefabricated blocks by pouring or shaking. It is mainly used for the lining parts of various industrial kilns such as incinerators and non-ferrous metal smelting furnaces.

Features Of Refractory Castable

High refractoriness, High refractoriness under load

High density, low porosity

Good slag resistance and corrosion resistance

High strength and wear resistance

Good resistance to flake performance

Good thermal shock stability

Scouring resistance

Good hot strength

Applications Of Refractory Castable

mainly used in heat treatment furnace,heating furnace,soaking pit furnace,tundish slag dam weir,seconclary refining and the catalytic cracking unit etc key part of kiln furnace and thermal equipment.