The cyclone separator (also referred to as cyclone), as the core separation equipment of Circulating Fluidized Bed (CFB) boilers, has become an indispensable component of the boiler system due to its advantages of simple structure, high separation efficiency, and convenient operation and maintenance. However, this equipment operates in an environment of prolonged high-temperature and high-dust gas scouring. In particular, the target area (the junction between the cyclone’s curved surface and the inlet flue) is a severe wear zone, which is highly prone to shedding failures of the wear-resistant and refractory castable lining. If not addressed promptly, it will not only affect the normal operation of the boiler but also may cause the shed materials to block the standpipe, thereby interfering with the operation of the material returner and resulting in more serious equipment damage.

- High-intensity Wear Under Extreme Working Conditions: After flue gas enters the cyclone, it undergoes forced rotation. As a key node where the gas flow direction changes abruptly, the target area is subjected to continuous scouring by materials with high flow velocity (gas velocity can reach 10-25 m/s) and high ash concentration. Long-term wear directly impairs the bonding strength between the castable lining and the substrate.

- Structural Hidden Dangers Arising from Construction Defects: During the construction of the target area, if the wear-resistant and refractory castable lining is poured excessively thick, a significant temperature gradient will form inside the material. During high-temperature operation, this gradient causes uneven internal stress within the material, laying the groundwork for crack formation.

- Cumulative Damage from Thermal Shock and Multiple Effects: Repeated thermal shocks caused by boiler start-ups, shutdowns, and load fluctuations, combined with factors such as temperature changes and material extrusion, continuously expand the internal cracks of the castable lining, ultimately leading to crack penetration and large-area spalling.

- Immediately cease boiler operation. It is strictly prohibited to perform maintenance work under high-temperature conditions to avoid personnel scalding or further damage to the material due to thermal expansion and contraction.

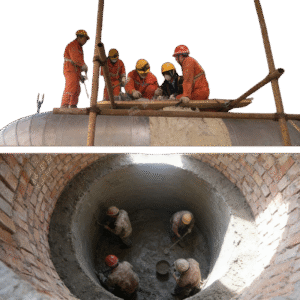

- After the boiler cools down to normal temperature naturally, arrange professional personnel to enter the cyclone for a comprehensive inspection. This includes assessing the scope of castable lining shedding, the looseness of the edges, and verifying the cause of shedding (e.g., whether it is caused by wear, presence of construction legacy defects, etc.) to provide a basis for subsequent repairs.

- Clean up debris and dust from the shedding area to ensure the repair base is clean and dry.

- Select wear-resistant and refractory materials consistent with the model of the original castable lining, and stir them uniformly in strict accordance with the construction ratio.

- Fill the stirred material into the shedding area and vibrate it densely to ensure seamless bonding with the surrounding original castable lining.

- Cure the material in accordance with the curing requirements, and only resume boiler operation after the strength meets the specified standards.

- First, use tools to remove the loose castable lining at the edges of the shedding area until a solid base is exposed, preventing re-shedding due to poor bonding between new and old materials after repair.

- Prioritize the use of corundum-based wear-resistant castable lining with excellent wear resistance as the repair material (Note: Corundum castable has weak thermal shock stability. During procurement, focus on verifying the product’s thermal shock resistance index; if necessary, select modified formulas with anti-cracking agents added).

- Apply an interface agent to the base before repair to enhance the bonding force between the new castable lining and the substrate.

- Pour the repair material in layers, and vibrate promptly after each layer of pouring to eliminate internal air bubbles.

- Extend the curing time to ensure the strength of the repair layer is fully up to standard, and put it into service only after passing the re-inspection.

- After repairing the castable lining shedding, continuously monitor the boiler’s operating status, focusing on the temperature changes and vibration of the target area to detect potential problems in a timely manner.

- During daily operation and maintenance, strengthen regular inspections of the cyclone’s target area. Endoscopes and other tools can be used to observe whether cracks or spalling precursors appear on the surface of the castable lining, achieving early detection and early treatment.

- During subsequent new construction or major overhauls, control the pouring thickness of the castable lining in the target area to avoid excessive accumulation leading to temperature gradients. Meanwhile, optimize the construction process to ensure the material is densely vibrated and internal defects are minimized.