Unveiling the Efficient Operation of a Rotary Kiln

As a core piece of equipment in the metallurgical, buil […]

Selection and Application of Refractory Materials for Hot Blast Stoves

Hot blast stoves, as core thermal equipment in industri […]

The “Golden Partnership” in High-Temperature Industries: Rotary Kilns and Refractories

In high-temperature industrial sectors such as cement p […]

Refractory Materials for Converter Steelmaking

The consumption of refractory materials for steelmaking […]

Ladle Refractory Linings in Steelmaking

The ladle used in traditional steelmaking processes, su […]

Refractory Castables: Composition, Properties, and Applications

Castables are granular and powdered materials made from […]

Structure and Components of Oxygen Top-Blown Converters in Steelmaking

Structure of Converter A converter is generally compose […]

Ceramic Firing Kilns: Classification & Tunnel Kiln Types

Firing is a crucial process in ceramic production, cond […]

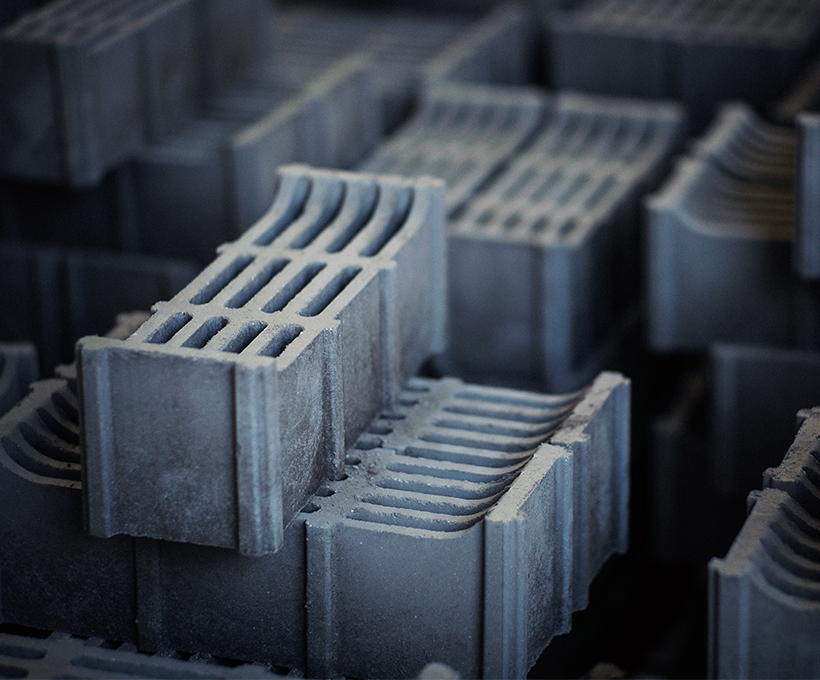

Refractory Materials for Ceramic Kilns Tunnel Kilns

A tunnel kiln consists of four parts: the kiln body, co […]

The Enduring Legacy of Clay Bricks: A Timeless Building Material

For millennia, clay bricks have formed the backbone of […]