Working Environment of Steel Ladles

Steel ladles are primarily used for containing molten s […]

The Power Players of High Alumina Bricks – Revealed!

High alumina bricks are widely used in various high-tem […]

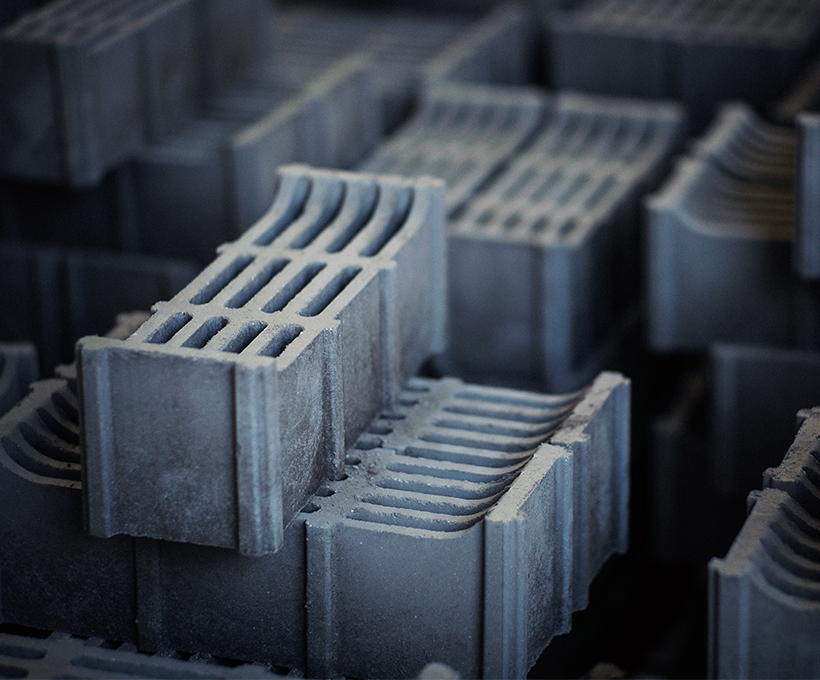

Application of Arc-shaped Refractory Bricks in Industrial Furnaces

1. Introduction Arc-shaped refractory bricks, also know […]

The History and Development of SK32 Firebrick

SK32 firebrick, a high-quality refractory material clas […]

High-Performance Fireclay Bricks for Cupola Furnaces and Boilers

When it comes to high-temperature industrial applicatio […]

High Alumina Bricks: Uses, Pros & Cons

High alumina bricks are essential in extreme heat indus […]

Key:Using High-Alumina Bricks at High Temperatures

High-alumina bricks are widely used in industrial furna […]

High-Performance Refractory Bricks for Extreme Heat

When it comes to high-temperature applications, not all […]

Custom Fire Bricks: Unleashing Their Unrivaled Advantages

Tailored Precision for Optimal Performance Custom fire […]

Special-shaped Silica Refractory Bricks: Meeting Customer Demands in China

In high – temperature industrial applications, sp […]