Address

No.108 Huaguang Road,Zibo City,Shandong Province,China

Work Hours

Monday to Friday: 9AM - 5PM

Address

No.108 Huaguang Road,Zibo City,Shandong Province,China

Work Hours

Monday to Friday: 9AM - 5PM

High-alumina bricks are widely used in industrial furnaces, kilns, and other high-temperature environments due to their excellent refractory properties, including high thermal stability, strong resistance to chemical corrosion, and good mechanical strength. However, to maximize their performance and lifespan, proper…

When it comes to high-temperature applications, not all materials can hold up under extreme heat and harsh environments. That’s where refractory bricks come in—engineered to resist thermal stress, corrosion, and mechanical wear. Whether it’s for steelmaking, cement kilns, or foundries,…

The quality of refractory clay directly impacts the performance of the final product. High-quality clay must possess good plasticity, sintering properties, and high refractoriness. China’s Liaoning, Shandong, and Shanxi regions are rich in high-quality refractory clay resources. Through careful selection…

Refractory bricks are essential materials used in high-temperature industrial applications, including steelmaking, cement production, glass manufacturing, and petrochemical processing. These bricks must withstand extreme heat, corrosion, and mechanical stress. Several global brands have established themselves as leaders in the refractory…

Introduction to Refractory Bricks Refractory bricks are specialized heat-resistant materials designed to withstand extreme temperatures without degrading. Made from high-alumina, silica, or fireclay, they offer excellent thermal stability, corrosion resistance, and durability. While widely used in industries such as steelmaking,…

At present, high – temperature operations are common across numerous industrial fields. From blast furnaces in steelmaking to searing kilns in glass manufacturing and high – temperature rotary kilns in cement production, these operations rely heavily on one key material:…

Industrial furnaces operate under conditions that would render regular materials unusable: extreme heat, chemical corrosion and mechanical stress. What allows industrial furnaces to thrive under these challenging conditions are specialized refractories designed specifically to meet the unique demands of industries…

In an era of rapid technological advancement, several other industries such as metallurgy, cement production, and energy generation will still be faced with heat management challenges perpetrated by the exceedingly high temperatures within their processes. Keeping with thermal efficiencies will…

IntroductionIn high-temperature industries such as steel, cement, and glass manufacturing, the reliability of refractory bricks is crucial for maintaining production efficiency and safety. Selecting the right supplier is a critical decision—but how do you ensure both quality and compatibility? Let’s…

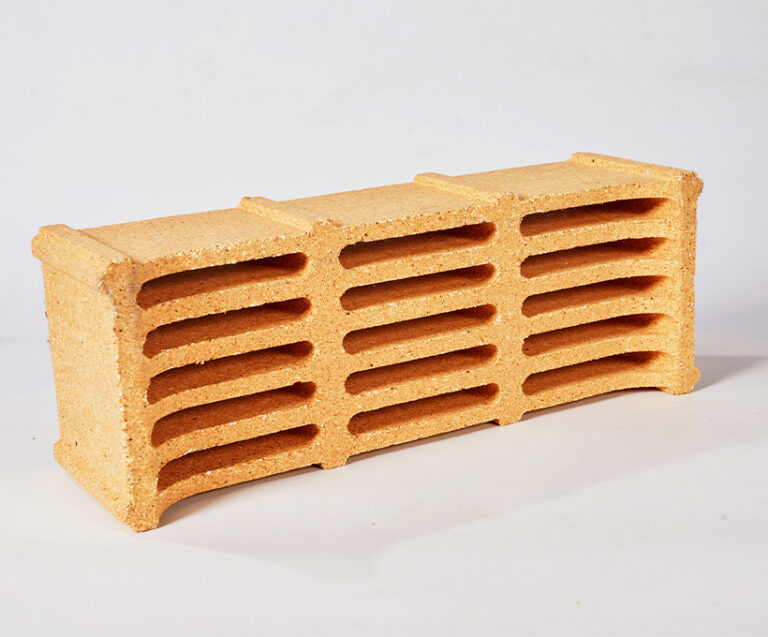

What Are High Alumina Bricks? Manufacturers produce high alumina bricks primarily from alumina (Al₂O₃) and other raw materials like clay. These bricks offer excellent thermal stability, high mechanical strength, and strong resistance to chemical corrosion. With an alumina content typically…