描述

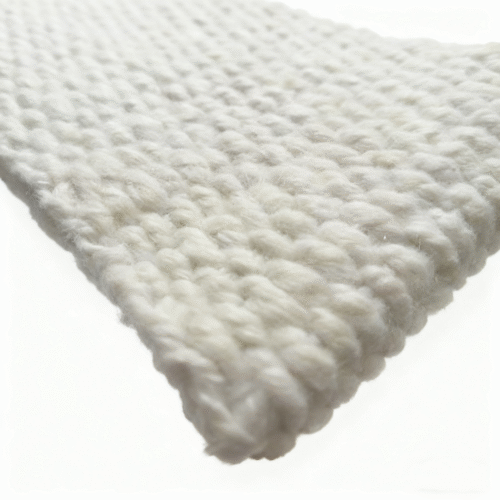

With the characteristics of low thermal expansion coefficient, low thermal conductivity, and energy saving, fused silica castable can reduce the thickness of the lining body. In addition, it also has the characteristics of high refractoriness, good volume stability at high temperature and good thermal shock resistance.

Technique Data of Fused Silica Castable:

| Item | Specification | |

| Ordinary | Superior | |

| SiO2 % | ≥70 | ≥96 |

| Al2O3 % | ≤24 | ≤0.5 |

| CaO % | ≤5.5 | ≤1.5 |

| Bulk Density, g/cm3 | ≥1.9 | ≥1.85 |

| CCS, MPa | ≥40 | ≥42 |

| PLC, % | -0.1~-0.41100℃×3h | -0.1~-0.31100℃×3h |

t is a low-expansion refractory material made from high-purity fused silica, featuring low thermal expansion, thermal shock resistance, and resistance to acid/molten metal corrosion. Its main uses include:

- Aluminum industry: Aluminum launders, filter boxes, and insulation furnace linings (leveraging its “non-stick aluminum” property to prevent metal adhesion);

- Glass industry: Sealing layers for glass furnace roofs and insulation layers for feed channels (suitable for high-temperature environments with large temperature fluctuations);

- Metallurgy/chemical industry: Linings for metallurgical kiln furniture and acid-resistant chemical reactors (combining acid corrosion resistance and high-temperature stability);

- Precision equipment: Some fused silica castables are also used in high-temperature components for semiconductor manufacturing (relying on high purity and low impurity content).