In high-temperature industrial sectors such as cement production, steel manufacturing, and non-ferrous metal smelting, the rotary kiln stands as the “heart” of the production line. Operating in a continuous 360-degree rotation, it performs critical processes like calcination and roasting of materials under extreme temperatures ranging from 1200°C to 1600°C. The key to the stable and efficient operation of rotary kilns lies in their “tacit cooperation” with various refractory materials. Today, we delve into this “golden partnership” of high-temperature industries.

Working Principle and Operating Conditions of Rotary Kilns

A rotary kiln is an inclined, rotatable steel cylinder lined with refractory materials. During production, materials enter from the kiln tail and move forward under the action of high-temperature airflow as the kiln rotates, undergoing physical and chemical reactions. In this process, the inner lining of the rotary kiln endures three “fatal challenges”:

- High-temperature impact: The maximum temperature inside the kiln can reach 1600°C, at which ordinary steel would quickly soften and deform, while refractories must maintain structural stability.

- Chemical erosion: Alkaline kiln dust in cement production and acidic slag in non-ferrous metal smelting continuously corrode the lining materials.

- Mechanical wear: Sliding of materials and stress from kiln rotation constantly abrade the surface of refractories.

“Customized” Refractories Shine in Different Zones

Rotary kilns are divided into zones such as the preheating zone, firing zone, and cooling zone based on temperature and material characteristics, with each zone imposing distinct requirements on refractories.

Firing Zone: The Primary Zone of High-Temperature Erosion

- Operating characteristics: Temperatures range from 1450°C to 1600°C, where materials undergo critical chemical reactions and endure intense erosion from alkaline kiln dust and slag.

- Suitable materials:

- Alkaline refractories: Magnesium-chrome bricks and magnesia-alumina spinel bricks, which exhibit excellent resistance to alkaline slag.

- Silica-alumina refractories: High-alumina bricks (with Al₂O₃ content ≥48%).

Preheating and Cooling Zones: Dual Challenges of Thermal Shock and Wear

- Operating characteristics: Frequent temperature fluctuations (800°C–1200°C) and intense material scouring.

- Suitable materials:

- Silica-alumina refractories: Mullite bricks, with low thermal expansion coefficients and good thermal shock resistance, effectively handle sudden temperature changes. Semi-silica bricks, cost-effective with good wear resistance and thermal stability, are commonly used in the cooling zone.

- Alkaline refractories: Magnesia-carbon bricks, combining the slag resistance of magnesia materials and the thermal shock resistance of graphite, are suitable for the preheating zone.

Kiln Head and Kiln Tail: Frontlines of Gas Erosion

- Operating characteristics: The kiln head contacts high-temperature clinker and strongly oxidizing gases, while the kiln tail faces alkaline dust and low-temperature corrosion.

- Suitable materials:

- Alkaline refractories: Magnesium bricks and dolomite bricks, with strong resistance to alkaline gas erosion, effectively protect the kiln head.

- Special refractories: Chromium- or zirconium-containing refractories, which offer good resistance to acidic gases, are used in kiln tail areas processing complex raw materials.

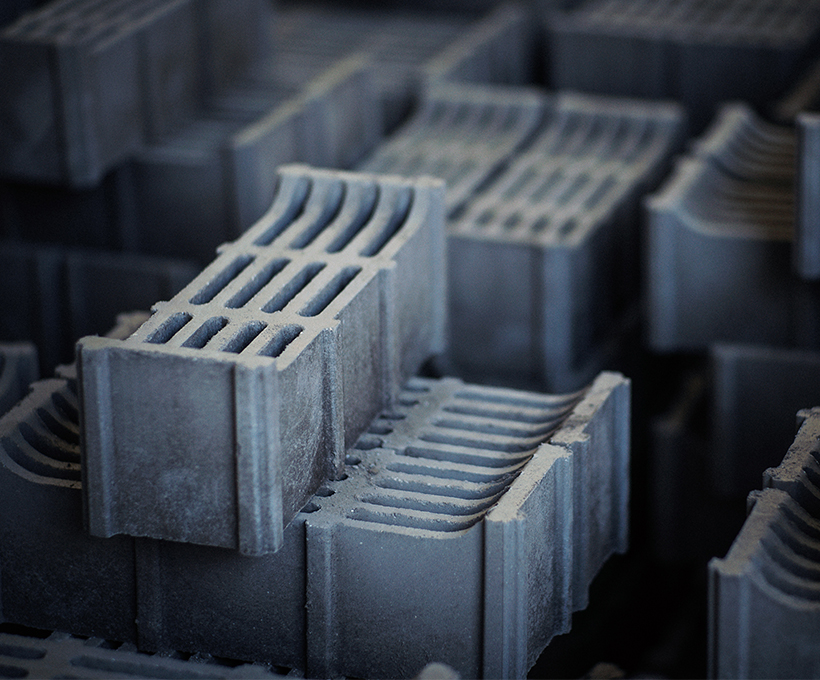

Clay Brick

Hard firebrick is a kind of alumina silicate brick containing 35-45%, and the refractories are SK 32-34. Brick is made of refractory clay, calcined limestone, mullite and other raw materials, with good wear resistance, peeling resistance, corrosion resistance. It has the characteristics of low porosity, high strength, heat peeling, wear resistance, creep resistance, etc., and is widely used in the lining of coke oven, glass kiln, cement rotary kiln, lime kiln, various incinerators and heating furnaces.